Pyrotechnic Chemistry

Pyrotechnic Chemical Compositions

Pyrotechnic chemical compositions contain an oxidizer component and a fuel component and are used in a wide range of applications: Delay Elements, Flares, Tracers, Igniters, Impulse Cartridges and Primers.

Since pyrotechnic compositions contain an oxidizer component, they do not rely on oxygen from external sources to sustain the reaction.

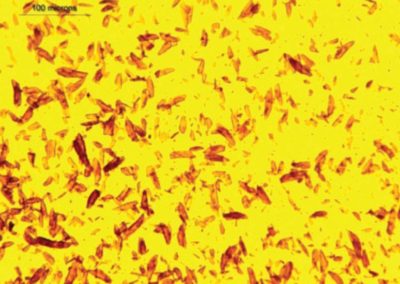

Pyrotechnic composition particles can be grains or flakes. Generally, the higher the surface area of the particles, the higher the reaction rate and burning speed. For some purposes, binders are used to turn the powder into a solid material.

| Chemical Name (click for spec sheet) | Specification |

|---|---|

| Aluminum Powder Atomized | MIL-P-14067 |

| Aminoguanidine Bicarbonate | MIL-A-60569 |

| Ammonium Picrate | MIL-A-60569 |

| Antimony Trisulfide Antimony Trisulfide (Sb2S3) is used in various priming mixtures, reacting vigorously with oxidizing agents | MIL-A-159D |

| Barium Nitrate | MIL-B-162 |

| Bismuth Oxide Bismuth Oxide (Bi2O3) is an innovative, non-toxic oxidizing system element used in small-arms priming mixtures. It replaces the highly-toxic Barium Nitrate, thus preventing potential health hazards in enclosed shooting areas. | |

| Black Powder | MIL-P-223 |

| Calcium Silicide | MIL-C-324C |

| Gum Arabic, Acacia Gum | JJJ-A-20 |

| Lead Azide, Dextrinated | MIL-L-3055C |

| Lead Azide, RD-1333 | MIL-L-46225C |

| Lead Nitrate Lead Nitrate (Pb(NO3)2) is an oxidizing agent qualified for use in the production of Lead Azide and Lead Styphnate. Total heavy metals (silver, copper, cadmium and iron) is below 10ppm. | MIL-L-20549B |

| Lead Styphnate | MIL-L-757A |

| Magnesium Oxide | MIL-M-51103B |

| Resorcinol | MIL-R-22578B |

| Sodium Picramate | |

| Tetracene | MIL-T-46938 |

| Waterproofing Compound | MIL-C-13783 |

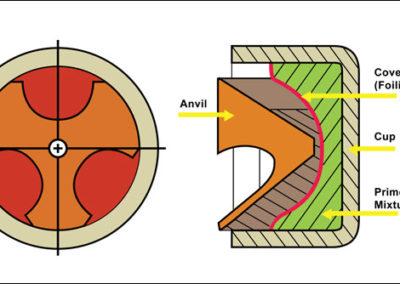

IPI provides our exclusive virgin Kraft paper surface-coated with nitrocellulose lacquer using state-of-the-art solvent coating

process yielding the highest quality sealing paper in the industry. IPI is recognized as the global leader of sealing paper in

accordance with MIL-P-60169B Type I and Type II.

IPI coated sealing paper provides the Primer manufacturer with uniform coating, superior thickness control and high tensile

properties to eliminate slipped foils realizing high productivity yield and throughput.

IPI Sealing Paper is available in White, Red and Green colors. Custom roll widths and lengths are available.

Used mainly in small arms ammunition for tracking, spotting, incendiary fire and fire control purposes.

| Chemical Name (click for spec sheet) | Specifiation |

|---|---|

| Barium Chromate | MIL-B-550 |

| Barium Nitrate | MIL-B-162D |

| Boron, Amorphous, Powder | MIL-B-51092 |

| Calcium Resinate VERIFY LINK - there's another variant of this | MIL-C-20470 |

| Calcium Silicide | MIL-C-324C |

| Calcium Silicate | MIL-C-51077 |

| Coating Compound | MIL-C-450 |

| Magnesium-Aluminum Alloy (powdered) | JAN-M-454 |

| Magnesium Powder | MIL-M-382C |

| Polyvinyl Chloride | MIL-P-20307 |

| Strontium Nitrate | MIL-S-20322 |

| Strontium Peroxide | MIL-S-612 |

Delay elements consist of a composition of chemicals (typically a fuel, an oxidizer and an additive) that burn at a slow, constant rate, encapsulated in a small-diameter tube inserted inside the ignition train. This provides a delayed ignition in fuze-based explosive trains, cartridge-actuated devices and other devices.

Delay time accuracy depends on the purity and precise particle size distribution of the chemicals in the composition, along with the exact ratio of materials in the mixture.

| Delay Composition | Spcification | Formulation | Specification |

|---|---|---|---|

| Manganese Delay Composition | MIL-M-21383A | Barium Chromate | MIL-B-550 |

| Lead Chromate | JAN-L-488 | ||

| Manganese Powder | JAN-M-476 | ||

| Tungsten Delay Composition | MIL-T-23132A | Barium Chromate | MIL-B-550 |

| Potassium Perchlorate | MIL-P-217 | ||

| Tungsten Powder Tungsten (chemical symbol: W; a.k.a. wolfram) is a high-density (19.3x of water, comparable to uranium or gold) rare metal. Its high density and hardness give it military applications in penetrating projectiles. As a delay composition, it is able to control burn time in pyrochemical compositions, based on both the percentage of tungsten in the composition and the tungsten powder’s particle size distribution. IPI supplies tungsten powder for use in delay compositions and in heavy metal penetrators. | AS-2686 | ||

| Zirconium Nickel Alloy Delay Composition | MIL-C-13739A | Barium Chromate | MIL-B-550 |

| Potassium Perchlorate | MIL-P-217 | ||

| Zirconium Nickel Alloy Powdered (Type I and II, 30/70) | MIL-Z-1410 | ||

| Boron/Barium Chromate Delay Composition (Less sensitive to static electricity and impact than zirconium-based ignition compositions) | N/A | Barium Chromate | MIL-B-550 |

| Boron Amorphous | MIL-B-51092 | ||

| Graphite | MIL-G-155 | ||

| Vinyl Alcohol Acetate Resin (VAAR) | MIL-V-50433 |

Primer Chemical Precursors

Picric Acid (2,4,6-Trinitrophenol)

- C6H3N3O7

- CAS No: 88-89-1

- UN No: 1344

- Hazard – Flammable Solid 4.1

Sodium Picramate

- C6H4N3NaO5

- CAS No: 831-52-7

- UN No: 1349

- Hazard – Flammable Solid 4.1